The article section highlights how Six Sigma significantly improves operational efficiency for organizations in Buena Park, California. This data-centric methodology, which includes lean Six Sigma principles, is structured into five phases—Define, Measure, Analyze, Improve, and Control (DMAIC)—to systematically address business challenges. Professionals who undergo Six Sigma training can apply this structured approach to enhance quality control, streamline operations, and achieve consistent outcomes. The highest level of expertise within this field is represented by the Six Sigma Black Belt, which signifies a leader's ability to manage complex process improvement initiatives with a focus on sustainability and scalability through ongoing monitoring and refinement.

The section specifically addresses the application of Six Sigma in various sectors, including manufacturing and services, where it has consistently proven its effectiveness by minimizing waste, increasing customer satisfaction, and enhancing overall efficiency. Aspiring professionals are encouraged to pursue Six Sigma certification as a means to demonstrate their commitment to continuous improvement and to gain the knowledge and skills necessary for leading operational excellence within their respective industries in California.

In summary, embracing Six Sigma methodology is crucial for organizations aiming to achieve operational excellence and maintain a competitive edge in Buena Park's dynamic business environment. The systematic DMAIC framework provides a clear path for identifying, analyzing, and solving problems, while Six Sigma training ensures that professionals have the tools and expertise needed to drive process improvements effectively. Attaining Black Belt status is a mark of high proficiency and leadership in this discipline, underpinning the transformative potential of Six Sigma across industries.

DMAIC process training stands as a cornerstone for quality improvement in Buena Park, CA, offering a structured approach to enhance operational efficiency through Six Sigma methodologies. This article delves into the essentials of Six Sigma, shedding light on its principles and their application within California businesses. We will explore the significance of Six Sigma certification pathways for aspiring Black Belts and examine the DMAIC framework in detail, emphasizing how it can be leveraged to optimize processes and drive performance. By understanding what Six Sigma is and mastering its fundamentals, organizations across Buena Park can achieve a competitive edge through improved quality and efficiency. Join us as we navigate the landscape of Lean Six Sigma and its transformative impact on businesses in the region.

- Mastering Six Sigma: An Overview of Lean Six Sigma and Its Impact on Buena Park, CA

- Six Sigma Certification Pathways: A Guide for Aspiring Six Sigma Black Belts in California

- What Is Six Sigma? Exploring the Fundamentals of This Quality Improvement Methodology

- Essential Six Sigma Training: Diving into Define, Measure, Analyze, and Control Phases

- Leveraging Lean Six Sigma Principles for Process Optimization in Buena Park Businesses

- Improving Efficiency with Six Sigma Methodology: Implementing and Maintaining Best Practices in California Organizations

Mastering Six Sigma: An Overview of Lean Six Sigma and Its Impact on Buena Park, CA

In Buena Park, California, the integration of Six Sigma methodologies has been a transformative force in various industries, from manufacturing to service sectors. Six Sigma, a data-driven approach to process improvement, focuses on improving the quality of process outputs by systematically removing defects and reducing variability. At its core, Six Sigma certification signifies the holder’s proficiency in its principles and techniques, demonstrating an ability to implement the methodology effectively. The Six Sigma black belt, for instance, is a highly respected designation indicative of advanced expertise in Six Sigma’s tools and concepts.

Lean Six Sigma, an amalgamation of Lean and Six Sigma, further enhances this approach by emphasizing waste reduction and maximizing efficiency. This hybrid model, often sought after through Six Sigma training programs, is particularly impactful for Buena Park’s businesses. By applying lean Six Sigma principles, organizations can streamline their operations, reduce costs, and improve product and service quality, which in turn drives customer satisfaction and competitive advantage. The Six Sigma methodology, with its systematic DMAIC (Define, Measure, Analyze, Improve, Control) process, has become a cornerstone for continuous improvement initiatives across Buena Park, leading to significant operational improvements and economic benefits.

Six Sigma Certification Pathways: A Guide for Aspiring Six Sigma Black Belts in California

In California’s business landscape, Six Sigma stands out as a methodology that champions process improvement and variability reduction. Aspiring Six Sigma Black Belts seeking certification in this state will find a wealth of resources and training programs dedicated to the Lean Six Sigma approach. The Six Sigma certification pathways are designed to provide professionals with a deep understanding of the Lean Six Sigma principles, which integrate lean thinking and Six Sigma methodologies to streamline processes and enhance efficiency. The journey through these certifications typically begins with Yellow Belt training, which offers an overview of Six Sigma concepts for team members and support staff. As practitioners advance, Green Belt certification deepens their knowledge in project management and data analysis, equipping them with the tools necessary to contribute significantly to process improvement initiatives. The pinnacle of this professional development is the Six Sigma Black Belt certification, which signifies mastery of the DMAIC (Define, Measure, Analyze, Improve, Control) process. This elite status indicates a profound expertise in leading complex projects and driving transformative change within organizations. Candidates who embark on this pathway gain not only the skills to impact their current roles but also to unlock career opportunities across various industries in California, where innovation and continuous improvement are paramount. Six Sigma training programs are tailored to cater to professionals at all levels, ensuring that whether you’re an individual contributor or a team leader, there is a pathway for you to advance your expertise in the Lean Six Sigma methodology and contribute to the ever-evolving landscape of process optimization.

What Is Six Sigma? Exploring the Fundamentals of This Quality Improvement Methodology

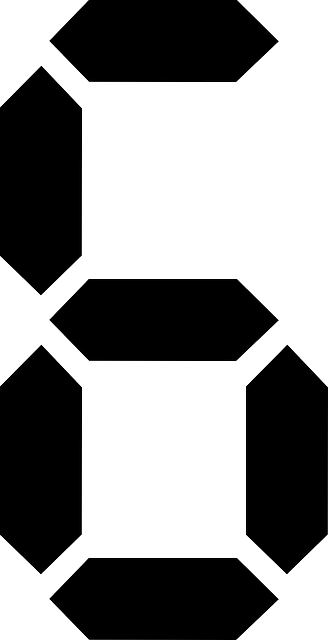

Six Sigma is a highly influential and data-driven quality improvement paradigm that aims to enhance efficiency and reduce variability in manufacturing or business processes. This methodology, which has its roots in the principles of scientific problem-solving, aims for near perfection by minimizing defects and errors in process outputs. It encompasses a set of principles derived from both traditional statistical process control and the modern lean management philosophies. The Six Sigma framework is characterized by its five key phases: Define, Measure, Analyze, Improve, and Control (DMAIC), which are essential to systematically address business challenges.

The Lean Six Sigma approach combines the lean principles of eliminating waste with the Six Sigma focus on quality and efficiency. This synergy often leads to significantly improved process outcomes. For those looking to specialize in this field, Six Sigma certification is a recognized credential that demonstrates proficiency and expertise. Aspiring professionals can pursue various levels of six sigma training, culminating in the coveted Black Belt status, which signifies the highest level of problem-solving ability and leadership skills within the Six Sigma methodology. Whether you are based in Buena Park, CA, or elsewhere, understanding the Six Sigma methodology can empower you to implement transformative changes in your organization, driving towards excellence in every process you oversee.

Essential Six Sigma Training: Diving into Define, Measure, Analyze, and Control Phases

Six Sigma is a data-driven methodology aimed at improving quality by reducing variability in manufacturing and business processes. Lean Six Sigma, an amalgamation of lean and Six Sigma principles, further streamlines processes for optimal efficiency. For professionals in Buena Park, CA, grasping the essential Six Sigma training is pivotal for driving process improvements and achieving high-quality outcomes. The Define phase initiates the Six Sigma process by clarifying objectives, scope, and resources required to deliver a project successfully. It’s where the ‘Delta Project’ of Buena Park City Services, for instance, would articulate its goals, constraints, and the problem statement that needs resolution.

Moving forward to Measure, this phase involves quantifying the root causes of defects or variations in the process. Six Sigma certification holders learn to establish metrics that accurately reflect process performance. This is where lean Six Sigma principles come into play, ensuring that measurements are captured with precision and relevance to the project’s objectives. The Analyze phase follows, where data collected during Measure is scrutinized to identify the cause-and-effect relationships. Utilizing tools like scatter diagrams, histograms, and process maps, Six Sigma practitioners dissect the data to pinpoint the exact factors influencing performance. Lastly, in the Control phase, processes are monitored, controlled, and, if necessary, fine-tuned to ensure continued conformity with customer specifications and process capability targets. This is where the Six Sigma methodology ensures that improvements are sustainable and that any deviations from target performance are promptly addressed. Engaging in Six Sigma training equips professionals in Buena Park with a robust set of tools and techniques, enabling them to contribute significantly to their organization’s efficiency and effectiveness.

Leveraging Lean Six Sigma Principles for Process Optimization in Buena Park Businesses

In the bustling business landscape of Buena Park, California, leveraging Lean Six Sigma principles has become a pivotal strategy for process optimization. Companies are increasingly recognizing the value of Six Sigma certification as a means to instill discipline and statistical thinking across all levels of their operations. The Six Sigma methodology, which encompasses a comprehensive approach to process improvement, is a powerful tool that can help Buena Park businesses achieve unprecedented levels of performance. By implementing the DMAIC (Define, Measure, Analyze, Improve, Control) process, organizations can systematically identify and eliminate defects in their processes, thereby enhancing efficiency and quality. Six Sigma training equips professionals with the skill set necessary to become adept at this rigorous methodology, often leading to the coveted title of Six Sigma Black Belt—a designation that signifies mastery in process improvement and a deep understanding of statistical techniques.

Furthermore, the Lean Six Sigma principles emphasize a data-driven approach to problem-solving, ensuring that business decisions are not only strategic but also grounded in empirical evidence. This approach has proven effective in various sectors within Buena Park, from manufacturing to services, demonstrating its versatility and broad applicability. By adopting these principles, local businesses can streamline their operations, reduce waste, and increase customer satisfaction. The journey towards Lean Six Sigma certification is not just about earning a credential; it’s about transforming the very fabric of how organizations function, ensuring that every process is fine-tuned for optimal output and minimal variation. This transformation is not without challenges, but with dedicated Six Sigma training and expert guidance, Buena Park businesses can navigate these changes successfully and secure a competitive edge in today’s dynamic marketplace.

Improving Efficiency with Six Sigma Methodology: Implementing and Maintaining Best Practices in California Organizations

The Six Sigma methodology stands as a beacon for organizations in Buena Park, California, aiming to streamline operations and enhance efficiency. This data-driven approach, with its lean Six Sigma principles at its core, emphasizes a structured process that encompasses defining the problem, measuring key processes, analyzing data, improving system performance, and controlling the processes for consistent results. Leveraging Six Sigma certification, professionals acquire the expertise to navigate this rigorous framework, which is crucial for maintaining high standards of quality control and operational excellence within California’s diverse industry landscape. The Six Sigma black belt, a pinnacle of this training, equips individuals with the skills necessary to lead process improvement projects, ensuring that lean Six Sigma principles are not just implemented but maintained through continuous monitoring and refinement. Organizations that embrace Six Sigma methodology typically experience significant improvements in efficiency, with reduced waste, lower costs, and a marked increase in customer satisfaction. The benefits of this approach extend beyond immediate gains, fostering a culture of quality improvement and a systematic problem-solving mindset across all levels of the organization. Six Sigma training, therefore, is an investment that yields both tangible improvements and intangible benefits, such as a more engaged workforce and a reputation for excellence in California’s competitive business environment.